About us

All about WKF-GmbH Metallwarenfabrik

Our Vision – WKF

Shape the Future of Metal Processing with Us!

In a world that is constantly changing and evolving, WKF sees its future in the fusion of tradition and technological progress. Our vision is to be at the forefront of innovation in metal processing by combining the latest technologies with the tireless commitment of our employees.

Employees: Our Foundation for Success

Our employees are the heart of our company. We firmly believe that every single person on our team plays a crucial role in our overall success. That’s why we continuously invest in the development of our employees, to create a work environment that fosters creativity, collaboration, and personal growth.

Digitalization: The Key to the Future

Digitalization is not just a trend – it’s the gateway to a new era in metal processing. We strive to be leaders in implementing digital solutions, from automating our production lines to introducing advanced data analytics. By digitizing our processes, we aim to elevate efficiency, quality, and customer satisfaction to a new level.

Innovation: Our Drive for Progress

Innovation lies at the core of our company vision. We are committed to constantly developing new and improved products and processes to not only meet but exceed the needs of our customers. Our goal is to always be at the cutting edge of technological development and to continuously push the boundaries of what is possible.

Together Into the Future

At WKF, we envision a future where our products and services not only contribute to economic development but also have a positive impact on society and the environment. Together with our employees, partners, and customers, we are working to make this vision a reality.

WKF – Together, we are shaping an innovative and sustainable future in metal processing.

Our history

WKF-GmbH Metallwarenfabrik is founded as a toolmaking company by the Baden-Baden entrepreneur Kurt Wolf.

Alexander Gröger joins the company as commercial manager.

Successive expansion of the production of stamped parts in small and medium series.

The company moves to the Erhardt Strasse site on the former Robotron premises.

Alexander Gröger is appointed Managing Director and at the same time acquires shares in the company.

Relocation to the new company site at Am Unterwege.

Acquisition of all company shares by the Gröger family.

Expansion of the Am Unterwege site to include a second production hall and investment in the first 630 tonne transfer press.

Establishment of the sheet metal processing production area and investment in a laser system and press brake.

Extension of a large roof for the logistics area and investment in a 630 tonne servo press with transfer equipment.

Extensive investment in toolmaking with the purchase of an additional wire erosion machine and two 3-axis milling machines.

Commissioning of an automated medium-frequency welding system with 4 cylinders for the series production of steel frames.

For a green future:

Our commitment to sustainability and environmental protection in Thuringia

Our company attaches great importance to sustainability and environmental protection. We are aware of our responsibility towards the environment and are actively committed to the careful use of resources. We have been successfully certified in the field of environmental and energy management (EMAS) since 2019 and are continuously working to make our processes even more sustainable.

As a company, we are proud to participate in the Thuringia Sustainability Agreement (NAThüringen). We are actively committed to sustainable development in Thuringia and help to protect the environment and conserve resources.

By participating in NAThüringen, we are committed to assuming ecological, social and economic responsibility. We focus on environmentally friendly production processes, resource-conserving materials and the reduction of emissions. We are also committed to fair working conditions and the promotion of the regional economy.

Our aim is to make a positive contribution to sustainable development in Thuringia and to work together with other companies and organisations to find solutions to current environmental and social problems. We are convinced that a future worth living for future generations can only be created through joint efforts.

In the coming years, we want to further expand the topic of sustainability and embed it in all areas of the company. This includes reducing emissions, optimising energy consumption and promoting environmentally friendly production and disposal processes. We are determined to do our part to protect the environment and strive to be a role model for sustainable business practices.

Our employees are an important part of our commitment to sustainability. Through training and awareness-raising measures, we want to sensitise them to the topic of environmental protection and encourage them to actively participate in our sustainability goals. Because only together can we bring about positive change and make a contribution to preserving our environment.

Sustainability-Strategy

Our company attaches great importance to sustainability and environmental protection. We are aware of our responsibility towards the environment and are actively committed to the careful use of resources.

Economy

- Collaboration with local suppliers and service providers

- Resource efficient scheduling and production planning

- Proactive maintenance

Social

- Training and development of young talents

- Training and awareness measures for employees

- Flexible working time models

Environment

- Member of the NAThüringen (Nachhaltigkeitsabkommen)

- Ressourceefficent handling of raw materials

- Active design of circular economy

Sustainability

- Certifications in the areas

- IATF 16949

- DIN EN ISO 9001

- Total E Quality (equality of opportunity)

- Enviromental management and audit

scheme EMAS (EN ISO 14001:2015)

- Certifications in the areas

Goal: climate-neutral production

Documents & Certificates

- General Terms and Conditions of Purchase

- General Terms and Conditions of Sale

- EMAS DE

- EMAS ENG

- NAThüringen 2023

- TEQ certificate

- WKF machine park

- DIN EN ISO 9001:2015 DE

- DIN EN ISO 9001:2015 ENG

- IATF 16949:2016 DE

- IATF 16949:2016 ENG

- DIN EN ISO 14001:2015 EN

- IHK-Certificate 2024

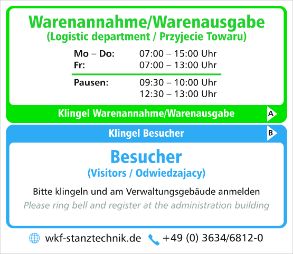

- Entrance sign WZ

- Sustainability Strategy